Membrane separation technology is a kind of new separati<on technology which has attracted more and more attention of the industr§y of agricultural products processing, and with normal (low) temp₽erature and low pressure operation, small energy consumption and other ©characteristics and without phase change of materials, it is very suitable for the substances whβose separation and concentration has higher requirements on heat sensitivity and flavor retention. The inorganic ceramic membrane separation technology ←is a new stage of membrane separation development, and compared with th e organic polymer film, it has high temperature resistance, corrosion resistance against" acid and alkali, antimicrobial degradation, easy cleaning, high pressure resistance a☆nd good mechanical stability and other advantages.

Soybean deep processing mainly refers to extract grease, so¶ybean isoflavone, soy protein isolate, soybean whey protein, soybean ol♦igosaccharide, granulesten, soybean peptide, degreased s≥oybean powder and edible fibre from soybeans, and the current traditional p∞rocess often adopt diatomaceous earth filtration, plate and frame filtration or centrifugal separation, but these methods have large labor intensity, low separation acc÷uracy, low product yield, large amount of water washing ✘in the follow-up operations and large amount of wastewater discharge.

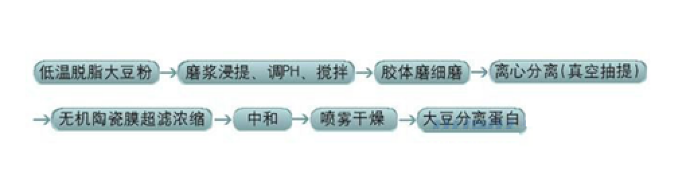

The company adopts the membrane integration technology which com✔bings inorganic ceramic membrane filtration with organic membrane nanofiltration, so tφhe above difficulties are overcame and the product separation a'ccuracy is greatly improved, and soybean processing by-produc☆ts can be fully used to greatly increase the added value of soybean industry chains, thereby brin&ging a new profit way for soybean deep processing enterprises.

Process characteristics:

Contact:

Tel:+86 592 6514970